Ventia's Engineering Services team adopted Industry 4.0 to digitise assets and improve connectivity, efficiency and asset security.

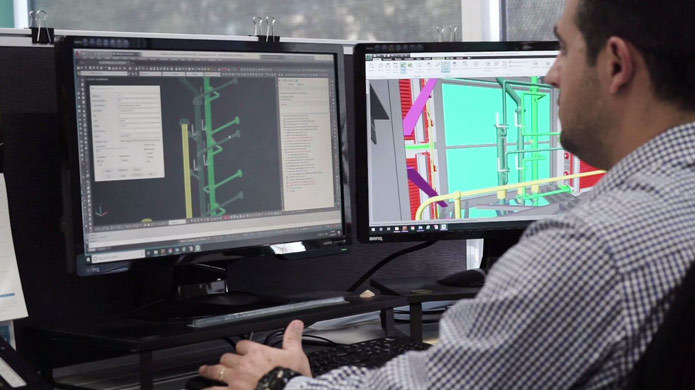

Building information modelling (BIM) is used to create a digital twin of buildings, plants and assets - accurate representations which can be used in asset databases, as-built plans and immersive 3D simulations. Digitalisation also makes it possible to correct errors and enhance industrial processes.

BIM can be used as a basis for decision-making. BIM models are produced as part of the design process in the oil and gas, wastewater, chemical and manufacturing industries and with the defence sector in Australia.

By combining engineering design expertise with the latest VR techniques, we are able to rapidly produce immersive digital twins of real-world assets which can be safely explored by operators. By using accurate models in the design process, engineers can easily detect clashes, reducing design iterations and eliminating spatial issues in construction and maintenance.

BIM technology is useful for brownfield sites where the plans may be incomplete, inaccurate or non-existent. To recreate facilities digitally, the asset is laser-scanned, capturing a millimetre-scale representation of the surroundings. Millions of 3D points on an object's surface are captured and each point's coordinates are recorded. This allows an object's actual surface to be represented in a discrete model with incredible accuracy. Additionally, these laser scans enable our engineering teams to safely explore hazardous facilities.

Using this technological approach, engineers can readily detect conflicts, enabling them to reduce the number of design iterations and eliminate spatial problems in construction and maintenance.